PTC heaters are made up of specialised heating discs made of sophisticated ceramic materials with a positive temperature coefficient. These heaters are safe, powerful, and energy-efficient, allowing for excellent heat production and transfer even in the tiniest of areas.

Have you ever had your heater break down just when you needed it the most? Have you ever heard of hot spots or overheating in vehicle seats? We’ve been relying on fixed resistance heaters for the majority of our demands for decades. When a single point sensor ‘assumes’ the temperature of the entire heater, safety is still an issue.

Despite the numerous problems that traditional heaters have faced, we continue to use them broadly throughout industries. Narain Cooling, on the other hand, now has the solution to all of these problems: PTC heating, a technology that prioritises safety.

What are PTC heaters?

PTC heaters are self-regulating heaters that operate in an open loop without the use of external diagnostic controls. PTC heaters use conductive inks printed on thin, flexible polymer-based substrates to generate heat, rather than the wires and coils used in classic fixed-resistance heaters.

They are perfect for goods that demand safer, faster, and more uniform heating due to their great dependability and efficiency. Because of the material’s characteristics, the PTC heater can function as its own sensor, obviating the requirement for external feedback controls. As a result, there is no chance of overheating with the heater.

What is a positive temperature coefficient?

When a material has a positive temperature coefficient, it means that as its temperature rises, so does its resistance to current. When the design temperature is reached, the current through these devices rises sharply because to the low resistance, but subsequently drops to zero. These gadgets are made to reach a certain temperature throughout the manufacturing process.

Types of PTC heaters

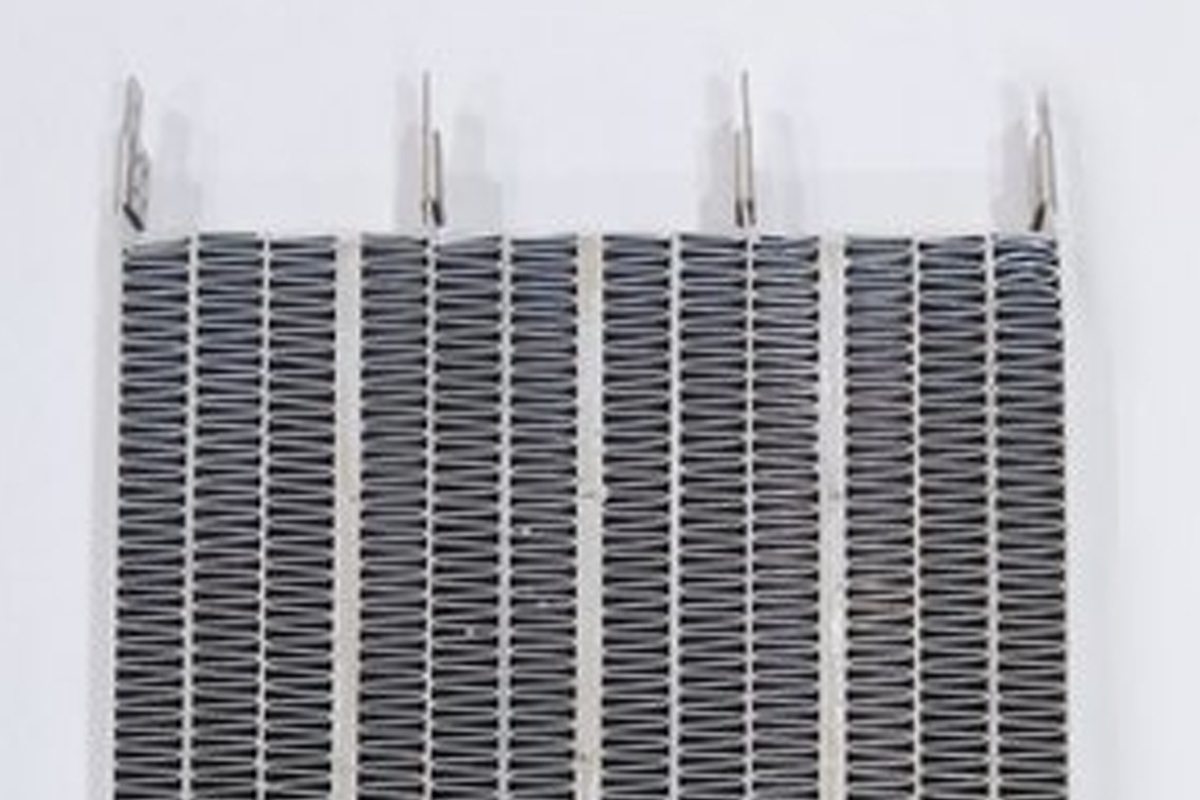

Fin elements and honeycomb shapes are the two types of PTC heaters. While both types of heaters have a number of advantages over traditional heaters, users should be informed of the advantages and disadvantages of each before choosing one.

The power consumed by PTC heaters

PTC heaters use all of its available power to quickly heat up and reach the desired temperature. As the temperature rises, the power consumption decreases. This dynamic heating system is not only efficient in terms of time and energy, but also in terms of effectiveness.

PTC heaters may work at temperatures ranging from -40°C to 70°C (-40°F to 158°F). During the design process, the threshold temperature is modified. Heaters with different temperature zones are possible, and the watt density can be adjusted with a few easy changes.

What do PTC heaters offer?

Conductive inks are genuinely authoring the success tale of printed electronics, such as PTC heaters, with a remarkable blend of performance and usefulness. They provide you the ability to create complex heating schemes. They’re also abrasion-resistant, cost-effective, and simple to manufacture in big quantities. Carbon conductive inks are screen printed on polymer-based substrates using PTC heaters. While polyester is the most common substrate material, other materials can also be employed. The PTC conductive inks can withstand several heating and cooling cycles. To avoid moisture infiltration and mechanical wear, the printed circuits are sealed with an adhesive laminate.

How are PTC heaters unique?

Heaters made with PTC cannot overheat. When the resistance of the device increases, the current through it lowers, making the gadget self-limiting. They can also be described as self-restraint. When the ambient temperature drops, the heater’s resistance drops, drawing more current and counteracting the cooling trend. Any tendency to raise its temperature, on the other hand, has the opposite effect. These qualities are not present in convection heaters.

The Point of Curie

PTC ceramics can be made with a variety of predetermined temperatures at which this drastic resistance shift occurs. The Curie point of the PTC heater is the temperature at which this happens.

More adaptability In the manufacturing industry

PTC heaters can be configured to function at temperatures ranging from -40 degrees Fahrenheit to 158 degrees Fahrenheit, making them ideal for a wide range of equipment design applications. The material utilised can be made in an infinite number of shapes and sizes. For specific uses, custom shapes can be created. Machined, drilled, bent, and curved PTC materials are all possible.

What are the advantages of PTC technology?

PTC Technology has considerable advantages in two critical areas, making it ideally suited and safe for use in the bilge region of your yacht. The first and most important consideration is safety. PTC heaters are self-limiting, which means that as they approach their design operating temperature, they automatically reduce their power consumption. Overheating is impossible with PTC heaters.

The maximum output level of the Xtreme Heater PTC element is chosen to offer enough heating power to maintain above-freezing temperatures within the engine compartment at low ambient temperatures.

Conclusion

The PTC element powers down to a minimum operating level without overheating; it stays operational as a convection heater to prevent freeze damage. When the heating system is suddenly subjected to a thermal load caused by lowering ambient temperatures or a consumer-induced event, such as opening the engine compartment hatch and allowing cold air in, the PTC heater from Narain Cooling will instantly raise its heating power to compensate for the heat loss. As soon as this is completed, the heater will return to treading water mode and stabilise at a reduced power level.